Lumet for real-time microstructure analysis of steel

Lumet, coupled with a thermomechanical simulator, is capable of swiftly and accurately replicating offline the precise processing schedules for each material while offering real-time microstructure analysis. The Lumet, a versatile tool for metallurgical studies, serves a wide range of purposes in both research and industrial settings.

The Future of metallurgical research in steel

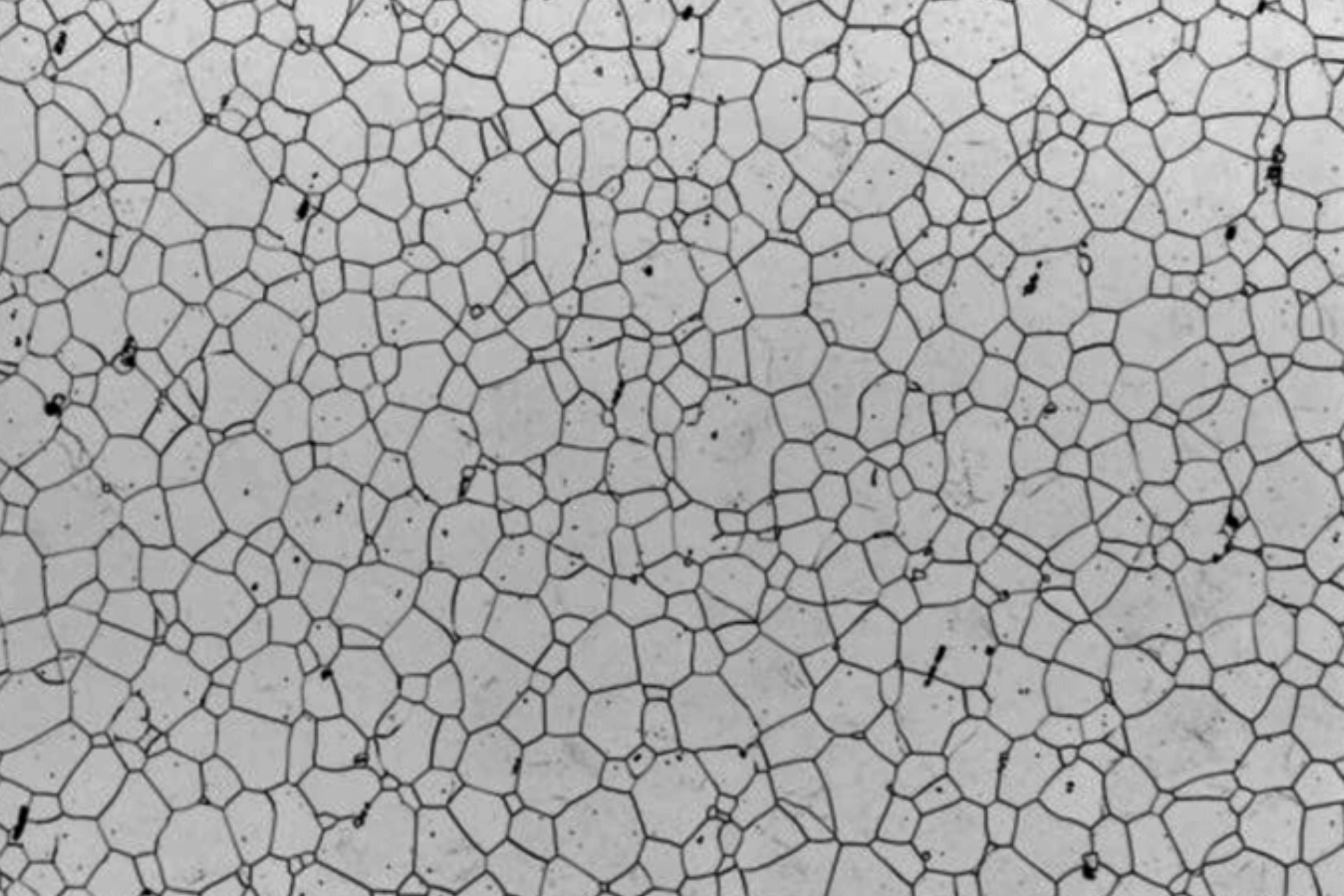

Perfecting the microstructure in steel production has always been a formidable challenge. The key to tailoring microstructures to meet the most stringent strength and toughness specifications in the market lies in the controlled rolling of steel. The microstructure of steel is its hidden fingerprint, holding the key to its mechanical properties, durability, and overall performance. It’s akin to the DNA of steel, determining its strength, toughness, hardness, and even its resistance to corrosion.

As the steel industry advances, there’s an increasing demand for steel products with highly specific properties tailored to diverse applications. This demand extends to sectors like automotive, aerospace, construction, and energy. Controlling the microstructure in steel production is essential for four key reasons. Firstly, it allows for customization, enabling steelmakers to meet specific requirements for strength, ductility, and hardness in various applications. Secondly, precise microstructure control enhances efficiency by optimizing processes, reducing energy consumption, and minimizing waste, ultimately lowering production costs. Thirdly, it ensures quality assurance by maintaining a consistent microstructure, thereby reducing the risk of defects and product failures. Lastly, in a competitive market, the ability to deliver steel products with superior properties through microstructure control becomes a crucial differentiator, providing companies with a competitive edge.

Why the Lumet in steel

Lumet, coupled with a thermomechanical simulator, is capable of swiftly and accurately replicating offline the precise processing schedules for each material while offering real-time microstructure analysis. The Lumet, a versatile tool for metallurgical studies, serves a wide range of purposes in both research and industrial settings.

Directly quantifying the dynamics of grain size evolution in advance alloy development

Enhancing the precision of microstructural analysis for annealing simulations

Validation of numerical simulation of thermomechanical processes in steel

Reducing the necessity for full-scale plant trials when developing new alloys.

Streamlining the troubleshooting process for annealing procedures, thus minimizing plant trials

Simulating the impact of line slow-downs on coil properties, enabling rapid response by production teams (such as decisions regarding scrap, re-processing, or retention)

The Lumet advantage

Directly quantifying the dynamics of grain size evolution in advance alloy development

Lumet, coupled with a thermomechanical simulator, is capable of swiftly and accurately replicating offline the precise processing schedules for each material while offering real-time microstructure analysis. The Lumet, a versatile tool for metallurgical studies, serves a wide range of purposes in both research and industrial settings.